The almond tree known under the Latin name “prunus dulcis” is a member of the rose family and hence closely related to the cherry, peach, apricot and rose. Cultivation of this frost-sensitive tree dates back around 4000 years. Almonds thrive particularly well in a warm climate and are grown, for example, in the vicinity of Alicante in Southern Spain.

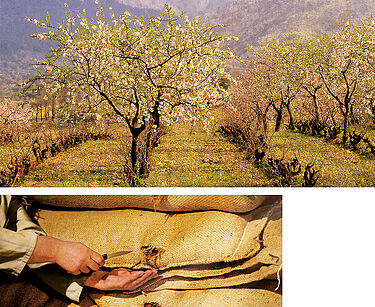

Aromatic almonds from southern climes are the most important raw ingredient in the production of high-quality Niederegger marzipan. Almond trees bloom from January to February. The vast groves then burst into magnificent displays of white and pink blossom. At this time of year, the managing directors and proprietors of the Niederegger family business, the Strait family, examine the quality of the blooms in person.

From March onwards, there is nothing more to be seen of the almond blossom. Harvesting takes place from early to mid September. The edible almond kernel is enclosed in a hard protective shell. After harvesting, the almonds are shelled, selected and packed locally ready for transport.

On arrival in Lübeck, the quality of every single consignment is checked once again by an independent laboratory before the almonds are released for production.

Niederegger products owe their unique quality not only to the quality of the raw ingredients and the traditional roasting method, but also to the right proportion of almonds to sugar. Everything else is a closely guarded family secret that has been passed down from one generation to the next for over 200 years.

At Niederegger, particular importance is attached to traditional craftsmanship. The almonds are blanched in a hot water bath – a quick and thorough way of removing their brown skins. They are then sorted, first by machine and then by hand, to ensure that only the very best almonds are processed. The selected almonds are rinsed again in large drums before being mixed with sugar. Rollers are used to grind the almonds and sugar, taking care to retain the texture of the almonds so that it is still perceptible to the tongue.

Afterwards, the raw mixture is roasted under the watchful eye of an experienced master roaster. This involves placing the mixture in a rotating boiler and heating it evenly over an open flame. The fine roasting aromas blend with the almonds and sugar to create a deliciously aromatic raw mixture. After cooling the mixture with cold air and leaving it to rest for a while, we add the secret Niederegger ingredient. Only then is the marzipan ready for turning into one of over 300 different products.